Winter is coming, you have to know the little common sense of PVC flooring!

2018/11/7 16:24:53 Browsing volume:The winter is approaching, the temperature is gradually decreasing, but the PVC flooring industry is still hot, and the construction of PVC flooring in winter needs to be more cautious. Otherwise, engineering problems will surely occur in the coming year.

1. Transportation and handling of PVC flooring

During the loading and unloading process of the cargo, it should be handled gently, the temperature in winter is low, the material becomes hard, and the violent loading and unloading will cause the floor to be damaged!

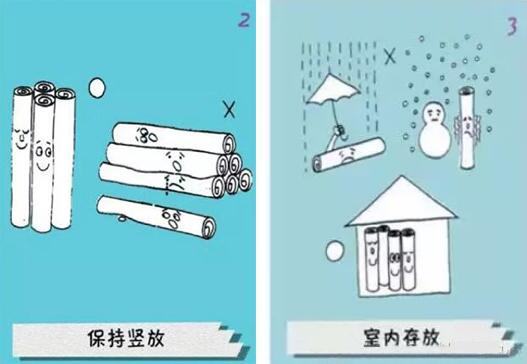

2, PVC floor storage

After receiving the goods, the PVC floor must be stored in a flat and dry place indoors, erected, not lying flat or leaning to the wall, and safety precautions.

Because the ground rubber is heavy, so as not to be pressed out of the folds, it is not easy to stretch and flatten, which will affect the on-site paving (ps: you can also receive the goods after the roll of the ground is rolled up to the site, the site temperature can not be lower than 15 °C, adapting to the situation of the site is a better choice.)

3. Influence of temperature on PVC floor construction

The construction temperature requirement of PVC floor construction is above 15 °C, and construction below 10 °C is prohibited.

Low temperature solution

1 using industrial heaters to heat up;

2 air conditioning heating;

3 heating up;

It is strictly forbidden to strictly prohibit: bake the floor with fire.

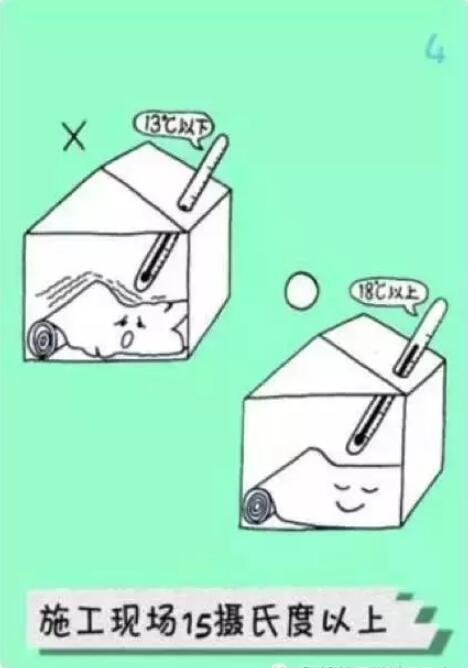

4, the impact of temperature on the construction of auxiliary materials

Interface agent

The essence of the interface agent is the emulsion. Under the environment of 5-8 °C, the interface agent can not form a film. After being applied on the ground floor, it will become a layer of powder. It can not play the role of infiltration and sealing, which leads to the self-leveling and the ground floor can not be firmly connected, and there is an empty drum crack in the later stage.

Self-leveling

If the temperature is too low, the self-leveling drying time will be too long or even frozen, and it will not be completely hydrated and dried in time. In the later stage, it will be dried, the surface will have no strength, and there will be quality problems such as surface sanding or cracking. Under the temperature rising environment, attention should be paid to the relative humidity of the indoor air. Too dry will directly affect the self-leveling cement moisture evaporation too fast, unable to complete the hydration process, resulting in self-leveling loss of strength.

Floor glue

The optimum construction temperature of glue should be above 15 °C (optimal above 18 °C). If the indoor temperature is below 10 °C, the bonding strength of the glue will be greatly affected, resulting in the adhesion of the floor to the ground is not strong, and later appeared. Degumming, curling and other issues. During the construction, the glue drying time of the glue is strictly controlled.

5, pre-shop

The floor is unrolled at low temperature. Unlike the normal temperature, the physical damage to the floor at low temperatures is unrecoverable. Therefore, when the floor reaches the destination, you should not rush to open the roll. Allow the floor to be stored at a temperature above 15 degrees Celsius for at least 24 hours. The roll can only be opened when the temperature of the floor and the room are the same.

When the temperature is low, the floor itself will become hard. When paving, it is necessary to use a pressure roller to roll multiple times before the glue hardens.

The above is the precautions for the winter construction of PVC floor. In order to ensure the quality of the project and you can better use the Haokang floor, please read it carefully and exercise carefully!